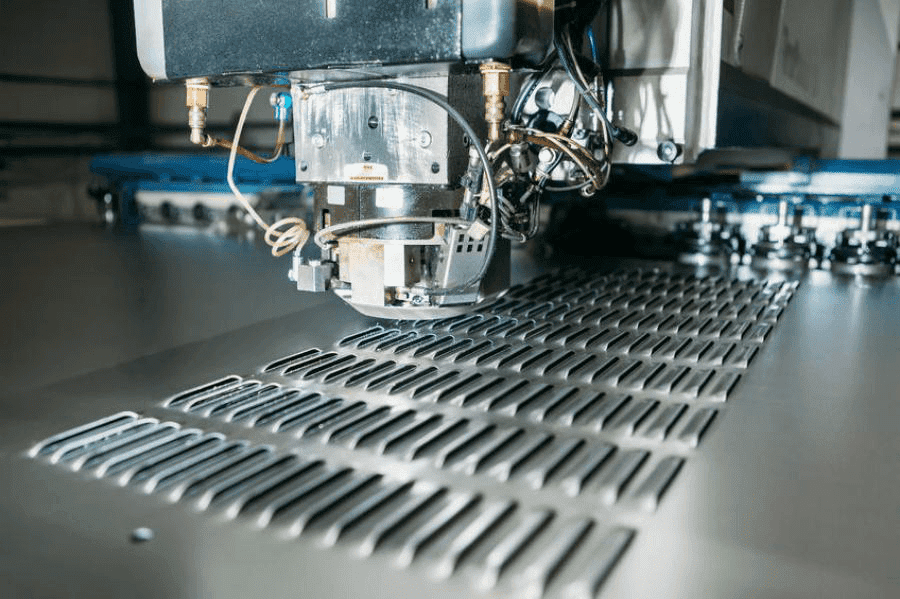

Sheet metal stamping is a process that involves using a machine to press metal sheets into specific shapes and designs. There are several related processes involved in sheet metal stamping, including:

1. Blanking: This is the process of cutting metal sheets into specific shapes using a punch and die set.

2. Piercing: This process involves making holes in metal sheets using a punch and die set.

3. Bending: Bending is the process of deforming metal sheets into specific angles by applying pressure.

4. Forming: This process involves changing the shape of the metal sheet without adding or removing any material.

5. Stretching: Stretching is the process of elongating metal sheets by applying force in a specific direction.

6. Drawing: This process involves pulling metal sheets into specific shapes using a punch and die set.

7. Roll Forming: This is a continuous process of shaping metal sheets by passing them through a series of rollers.

8. Embossing: Embossing is the process of creating a raised or sunken design on metal sheets.

9. Coining: This process involves using a punch and die set to apply high pressure to metal sheets, creating a precise shape or design.

10. Flanging: This process involves bending the edges of a metal sheet in a specific direction to create a flange.

Each of these processes plays a crucial role in the overall process of sheet metal stamping, and they are typically performed in a specific sequence to produce the desired end product.